Contacts

About the company

Manufacturing manhole covers and gully gratings by order

You can order manhole covers and gully grates in any number of non-standard sizes (even 1 piece). To do this, you need to contact the pre-orders department of our company by phone: +421950614826 or by e-mail panov.trading@gmail.com

Ten reasons for you to choose TDS

For 15 years of work on the market, our company has become a leading company, and its products are distinguished by the optimal combination of price, functionality and durability.

1. Uniqueness.

Our company is a leader among manufacturers of polymer manhole covers and gully grates in Ukraine, because:

• we were the first to create a plastic manhole cover;

• only we have a certified laboratory for testing all manufactured products;

• we are the leaders in sales among polymer gully grates and manhole covers;

• only our products, thanks to special testing and unique material properties, withstand the required load.

2. No sand in the products.

The composite material from which our manhole covers and gully grates are made does not contain sand. Our products have unique properties, are distinguished by ideal characteristics – durability, lightness and strength.

3. Cost.

The price of our products will pleasantly surprise you because the products of the TDS company are 60-80% cheaper than their metal counterparts.

4. Light weight.

Our polymer manhole covers and gully grates are 60–80% lighter than their metal counterparts. This makes our products very easy to transport (reduce the cost of necessary equipment and labor), installation and operation (this can be done quickly and easily by one person).

5. Anti-vandalism.

Plastic manhole covers are not interesting for thieves.

6. Compliance with the requirements of modern technological regulations.

All our products are developed and approved by the “Scientific Research Center for Standardization, Metrology and Certification of Ukraine”, they have properties and characteristics that meet the requirements and norms of state standards of Ukraine and Europe: DSTU (V.2.5-26: 2005), EN 124 and GOST (3634-99 / B).

7. Resistance to environmental influences.

Resistance to environmental influences.

8. Chemical resistance.

Manhole covers are often used in sewage / sewer manhole covers, resulting in increased levels of microbiological corrosion. Our manhole covers are not corroded.

9. Low abrasion resistance.

The abrasion coefficient of our manhole covers is 0.06 – 0.12 g / sm2

10. Our gully grates and manhole covers are non-conductive.

How can you save money with our polymer manhole covers?

Today cast-iron products, in particular manhole covers of inspection wells, are not made from the same cast iron that was produced 100, 50, 30 and even 10 years ago. Therefore, there can be no question of any reliability of the metal manhole cover, which we are convinced of when we see the broken products on the wells. In addition, they are quite expensive, and even about the speed of disappearance of the cover from your well, and sometimes even the shell. As a result, there are some disadvantages, especially if we take into account the cubic meters of contaminated emissions into the environment during the processing of cast iron.

Consider purchasing “cheap” polymer sand hatches. You will forget about their cheapness right after the purchase, when you start thinking about delivery and installation. Finally, the joy of the acquisition will dissipate with the onset of frost and the appearance of a “good” crack in the hatch. Products with sand deteriorate quickly, much faster than plastic and cast iron.

Unique features of plastics

Plastics have a set of properties that are extremely valuable for construction. One of their main advantages is their low bulk density (15 – 1500 kg / m3). On average, plastics, with the exception of foams, are 2-3 times lighter than aluminum and 5-8 times lighter than steel.

Another important advantage of plastics is their high strength. In this respect, plastics are superior to many traditional building materials – concrete, brick, wood. Plastics with sheet-like and fibrous fillers have the highest strength indicators.

An indicative characteristic of the structural properties of plastics is the ratio of the strength of the material to its bulk density – the coefficient of structural quality. Plastics, mainly laminates, have a high structural quality factor of 2.2 – 2.5, while for masonry it is 0.02; for concrete – 0.06; steel – 0.5; pine wood – 0.7.

Plastics have low thermal conductivity, which is important for enclosing structures. In dense plastics, the thermal conductivity coefficient ranges from 0.22 to 0.68 W / m ° C, while for porous plastics it is 0.03 W / m ° C. This property allows manufacturers to make building envelopes thin, lightweight, but durable.

Chemical resistance is a very important property of plastics, which depends not only on the properties of the polymer, but also on the properties of fillers, plasticizers and other components. Especially resistant to corrosion are plastics based on polyethylene, polystyrene, polyvinyl chloride, epoxy polymers.

A valuable quality of many plastics is their low abrasion. Polymeric flooring materials have the same abrasion coefficient as ceramic tiles (0.06 – 0.12 g / cm2), and even lower than that of stone slabs.

An important characteristic of many plastics is their high impact resistance, or toughness. Its value ranges from 10 (plexiglass) to 500 kJ / m2 (fiberglass).

In addition to excellent physical, mechanical and chemical properties, plastics have valuable technological properties. They are relatively easy to form (by casting, pressing, stamping, etc.), they can be welded and glued together and with other materials, which makes it possible to create sealed structures, to carry out hydro and vapor barrier.

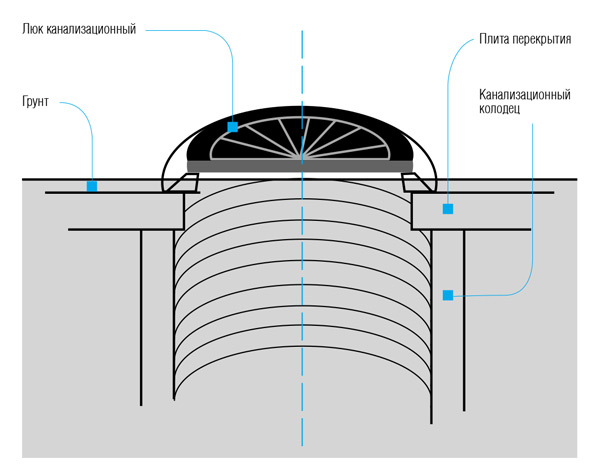

Class A manhole cover installation

Installation and installation of sewer hatches should be carried out in accordance with strictly established rules, because only in this case they will be completely safe for both pedestrians and other road users.

Installation procedure

• Install the hatch ring on the reinforced concrete surface..

• Fill the ring with concrete.

• Insert the manhole cover into the ring.

Note: The manhole cover of wells that are located in built-up areas without road surfaces should rise 50 mm above the ground. Around the hatch, a 1.0 m wide blind area with a slope from the hatch cover should be provided.

Sewer lines between wells must be laid straight; in places where the network turns, the slope of the line changes, the diameter of the pipes changes, wells must be built on which the installation of sewer hatches will be carried out. Pipes and channels in wells must be connected at the top of the pipes or at the water level in order to reduce the formation of backwater in the higher sections of the network as much as possible. When turning the route, pipelines with a diameter or height of 1.2 m and more can be arranged outside the inspection wells along curves with a turning radius equal to at least five pipeline diameters, and at the beginning and at the end, the installation of sewer wells must be done.

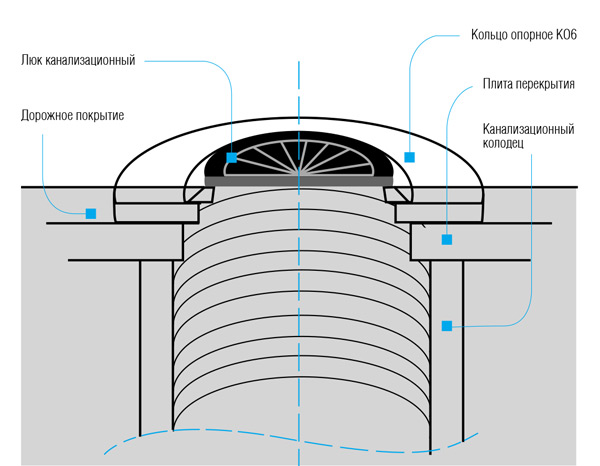

Class B and Class C manhole cover installation

Intervals between inspection hatches.

When installing the hatch, it should be borne in mind that the distance between linear-type manholes depends on the pipe diameter.

d = 150 mm – 35 meters;

d = 200 mm – 50 meters;

d = 500 mm – 75 meters;

d = 700 – 900 mm – 100 meters;

d = 1000–1400 mm – 150 meters;

d = 1500–2000 mm – 200 meters;

d > 2000 mm – 300 meters.

Installation procedure

• Install the hatch ring on the reinforced concrete pavement with ears along the direction of traffic.

• Fill the ring with concrete / road surface.

• Insert the manhole cover into the ring.

Note: The hatch body is installed on a concrete or reinforced concrete structure, the technical requirements for which are determined by the current GOST 8020-90 “Concrete and reinforced concrete structures for sewer, water supply and gas supply networks”. The main purpose of the support ring is to redistribute the specific load in order to protect the base slab from destruction. As shown in the figures, the well is covered with a floor slab on which the support ring is mounted. The hatch body is installed on the support ring. The manhole cover should be flush with the surface.